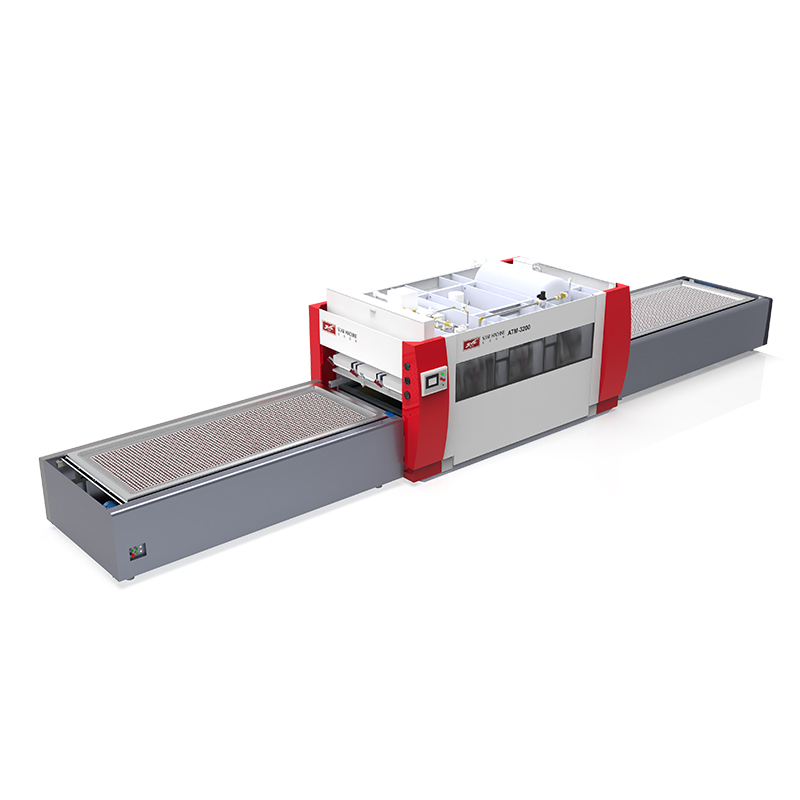

Wholesale Price PVC Vacuum Membrane Press Machine - ATM-3200 Auto pin membrane press machine – FELTON

Wholesale Price PVC Vacuum Membrane Press Machine - ATM-3200 Auto pin membrane press machine – FELTON Detail:

Vacuum membrane press machine ATM-3200

It is used to work with various high-quality PVC, high gloss, hot transfer and veneer at one side. Mainly press the cabinet,wardrobe,and other furniture.

The products are of high quality, and will not peel off,the line and groove are clear.

This machine can choose silicon pre-press mode (loading positive pressure twice through silicon rubber sheet) to improve the production quality.

Samples

ATM-3000II main specialties: humanized designs

Technical Specifications

Operation

3. Press”choice”(figure 2),change working model to “manual”(figure 3)

First start Hot Transfer pump to force Transfer Oil in a movement of circuit, and five minutes later, turn on the Heating Switch. When shutdown working, firstly turn off Heating Switch, and keep oil pump still working until 30 minutes later, when Hot Transfer Oil cool down, then oil pump could be turned off

4. Working model choice: F1 loading once, F2 loading twice,

F3 veneer model, F4 silicone prepress

Button F1-F4 lie in right of screen, press as choosing; different models recording to different product technology, temperature adjusted by model changing. Models choice only works in state of ‘ Manual ‘. Cannot change model in automatic operation.

5. Temperature setting: air temperature set to be 100. start lower heating board when make high gloss pvc, generally it is 55℃, in sumer, according to the indoor temperature, no more than 50℃

Upper heating board temperature:

set by working model and pvc. when in F1 and F2, Set 135℃ for flat gloss pvc, 100℃ for high gloss pvc; when in F3, 120℃ set for veneer products; when in F4, 85℃ set for high gloss pvc.

6. Parameter setting

chose “choice” to “parameter setting”, like figure 4. First chose working model, then next, get in the figure of parameter setting (figure 5 and 6). Attention, two figures must be both set, no forgotten.

The basic parameter set followed for reference, there will be some adjustment when work. Set 0.45mm high gloss pvc as sample

F1 model parameter

F2 model parameter

F3 model parameter

F4 model parameter

working pressure set:

Product detail pictures:

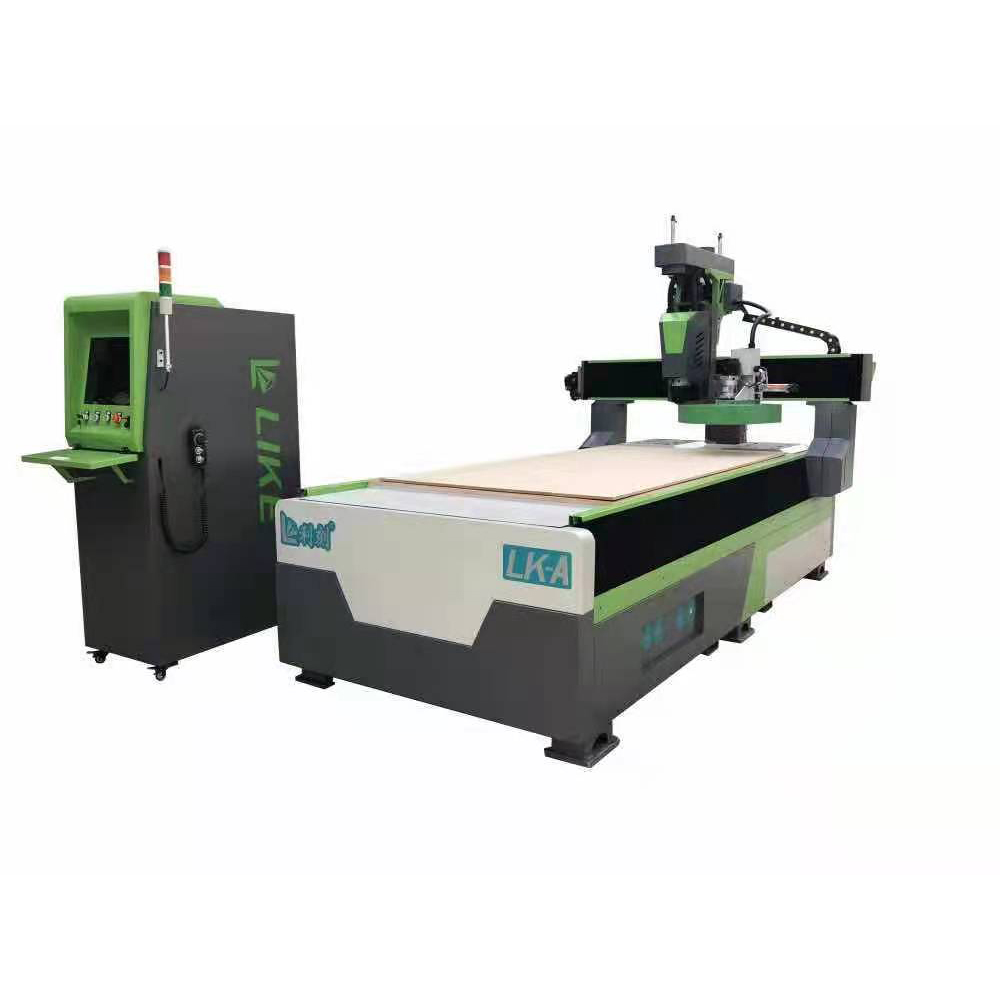

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for Wholesale Price PVC Vacuum Membrane Press Machine - ATM-3200 Auto pin membrane press machine – FELTON , The product will supply to all over the world, such as: Italy, Ecuador, Moldova, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!