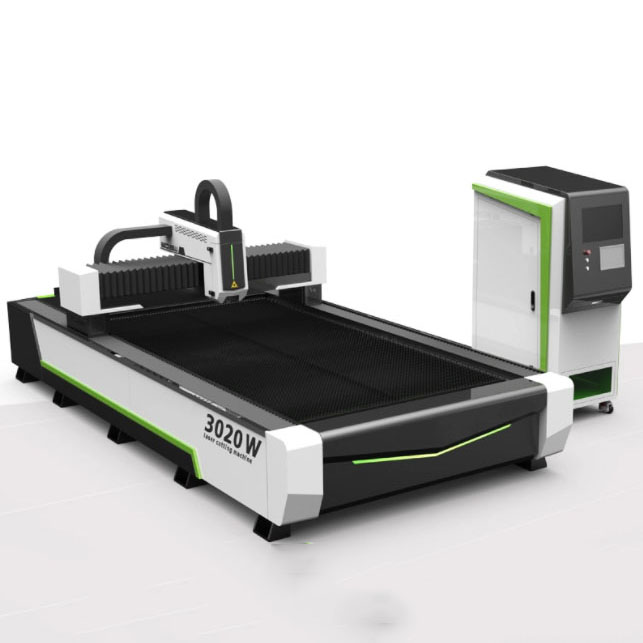

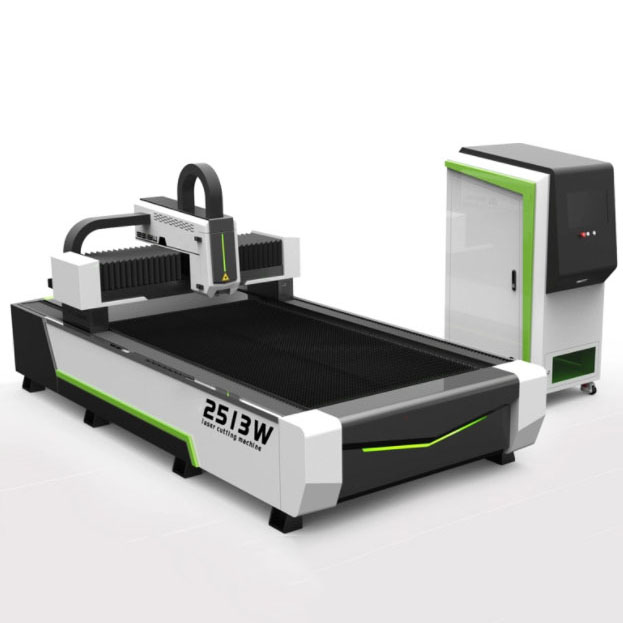

Factory Low Price Vacuum Laminating Press – 2513W Flat Metal Board Laser Cutting Machine – FELTON

Factory Low Price Vacuum Laminating Press – 2513W Flat Metal Board Laser Cutting Machine – FELTON Detail:

Material application

Carbon steel, stainless steel, galvanized steel, color steel, electrolytic plate, aluminum plate, aluminum alloy, brass, red copper, manganese steel, silicon steel, titanium plate and other metal materials.

Industry application

Kitchen appliances, sheet metal cabinet, mechanical equipment, hardware lighting, door&window manufacturing, advertising signs, auto parts, decoration, shipping and aviation, medical equipment, mining equipment, animal husbandry machinery, agricultural machinery, iron tower industry, clothes hanger, shelf and metal processing industry

laser laser cutting machine Product Feature

1)Lower operation cost,every hour only consumed 0.5W to 1.5W electricity.

2)High performance qualified fiber generator,which is high reliability and longevity of service.

3)Higher cutting speed and efficient,Max cutting speed can be reach 10m/min in cutting 1mm mild steel.

4)Free maintenance for fiber laser generator.Max life reach to more than 100000 hours.

5)Smooth cutting surface,little deformation,pretty leveling appearance.

6)Import transmission parts and servo motor, high dynamic movement performance, high cutting precision.

7) Dedicated software enables graphic or text into instantly designed pr processed.

Technical Data

| Name | laser cutting machine |

| Model | PE-3015 |

| Power | 2000W |

| Working area | 3000 ×1500 x 150mm |

| Minimum cutting line width | 0.1mm |

| Rated output power | 2000W |

| X, Y-axis positioning accuracy | ≤±0.01mm |

| Repeated positioning accuracy of the table | ≤±0.01mm |

| Max. Cutting Thickness | 15-20 mm (Carbon Steel) |

| Transmission Method | High Precision Gear Transmission |

| Table-driven system | Japanese Import Panasonic Servo Motor & Driving System |

| Volume | 4.6*2.3*1.8m |

| Focus Method | Dynamic Following and Automatic Adjust Focusing |

| Water cooler | 2kw |

| Electricity power | 380v 50Hz±10% |

| Red light spot position | yes |

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for Factory Low Price Vacuum Laminating Press – 2513W Flat Metal Board Laser Cutting Machine – FELTON , The product will supply to all over the world, such as: Russia, Angola, Porto, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.