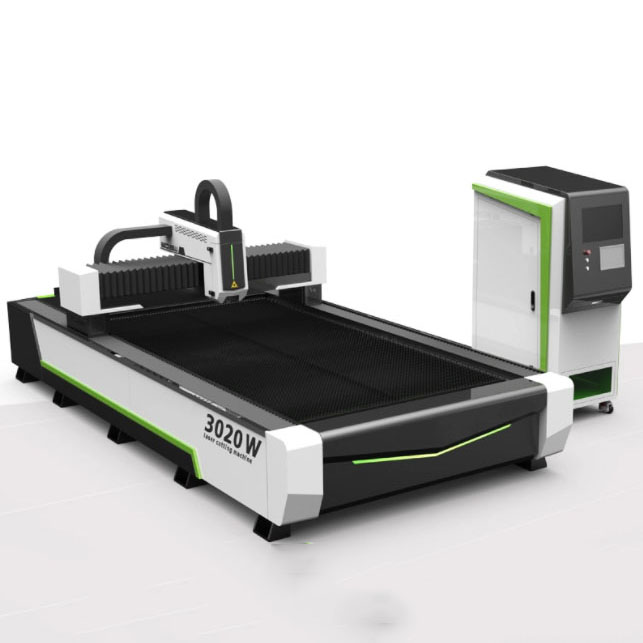

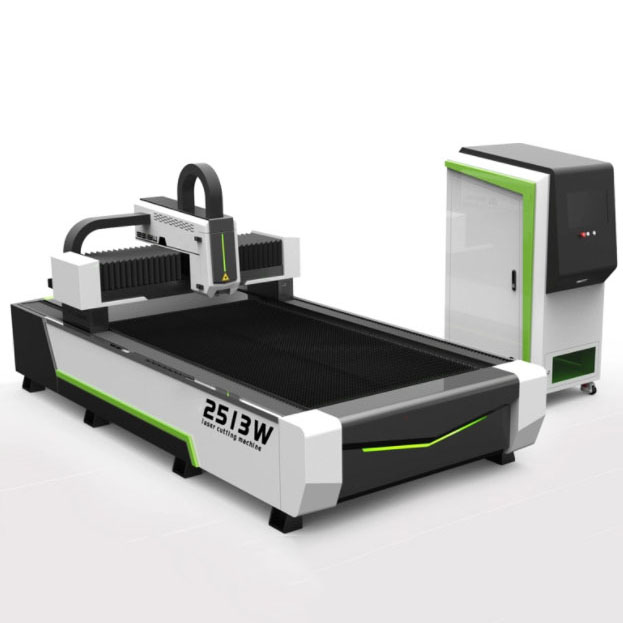

Factory Outlets Mini Fiber Laser Marking Machine - 2513W Flat Metal Board Laser Cutting Machine – FELTON

Factory Outlets Mini Fiber Laser Marking Machine - 2513W Flat Metal Board Laser Cutting Machine – FELTON Detail:

Material application

Carbon steel, stainless steel, galvanized steel, color steel, electrolytic plate, aluminum plate, aluminum alloy, brass, red copper, manganese steel, silicon steel, titanium plate and other metal materials.

Industry application

Kitchen appliances, sheet metal cabinet, mechanical equipment, hardware lighting, door&window manufacturing, advertising signs, auto parts, decoration, shipping and aviation, medical equipment, mining equipment, animal husbandry machinery, agricultural machinery, iron tower industry, clothes hanger, shelf and metal processing industry

laser laser cutting machine Product Feature

1)Lower operation cost,every hour only consumed 0.5W to 1.5W electricity.

2)High performance qualified fiber generator,which is high reliability and longevity of service.

3)Higher cutting speed and efficient,Max cutting speed can be reach 10m/min in cutting 1mm mild steel.

4)Free maintenance for fiber laser generator.Max life reach to more than 100000 hours.

5)Smooth cutting surface,little deformation,pretty leveling appearance.

6)Import transmission parts and servo motor, high dynamic movement performance, high cutting precision.

7) Dedicated software enables graphic or text into instantly designed pr processed.

Technical Data

| Name | laser cutting machine |

| Model | PE-3015 |

| Power | 2000W |

| Working area | 3000 ×1500 x 150mm |

| Minimum cutting line width | 0.1mm |

| Rated output power | 2000W |

| X, Y-axis positioning accuracy | ≤±0.01mm |

| Repeated positioning accuracy of the table | ≤±0.01mm |

| Max. Cutting Thickness | 15-20 mm (Carbon Steel) |

| Transmission Method | High Precision Gear Transmission |

| Table-driven system | Japanese Import Panasonic Servo Motor & Driving System |

| Volume | 4.6*2.3*1.8m |

| Focus Method | Dynamic Following and Automatic Adjust Focusing |

| Water cooler | 2kw |

| Electricity power | 380v 50Hz±10% |

| Red light spot position | yes |

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Factory Outlets Mini Fiber Laser Marking Machine - 2513W Flat Metal Board Laser Cutting Machine – FELTON , The product will supply to all over the world, such as: Pretoria, Los Angeles, Cannes, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!