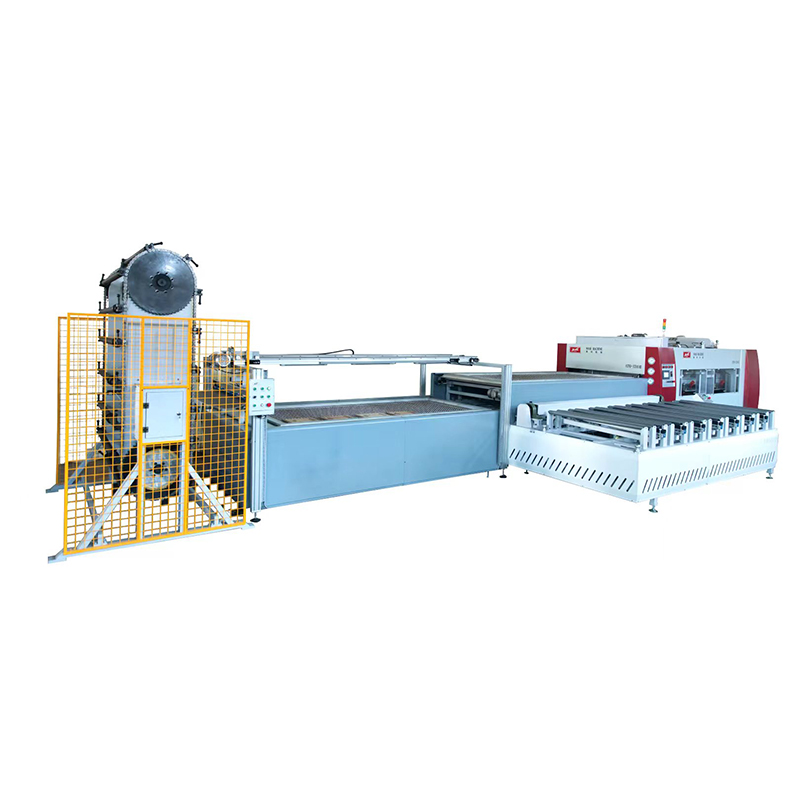

Automatic pin vacuum membrane press machine ATM-3200II

Automatic pin vacuum membrane press machine ATM-3200II

It is used to work with various high-quality PVC, high gloss, hot transfer and veneer at one side. Mainly press the cabinet,wardrobe,and other furniture.

The products are of high quality, and will not peel off,the line and groove are clear.

This machine can choose silicon pre-press mode (loading positive pressure twice through silicon rubber sheet) to improve the production quality.

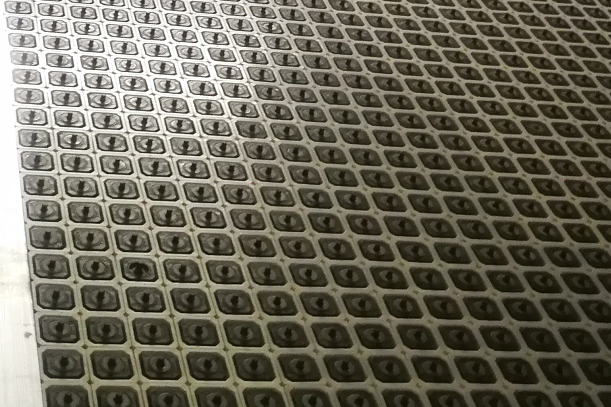

Samples

vacuum pump,adopting German technology, its horsepower is strong, and long service life.

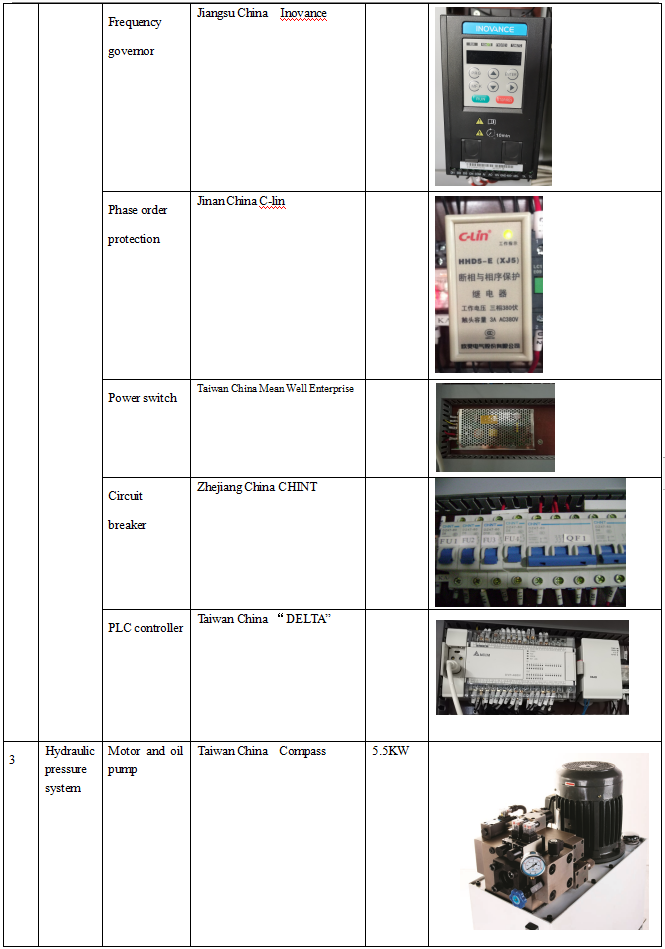

The main engine of hydraulic pressure system adopts international advanced system.The plate plug-in principle features advanced structure, low malfunction rate, high flow and rapid pressure (pressing time about 5 seconds instead of traditional pressing time 15-20 seconds) thus promoting production efficiency.

The operation system chooses the international branded “Delta” PLC control equipment and the large man-machine touch screen . The machine is easy to control, and the technology is highly advanced. The automatic degree is very high.

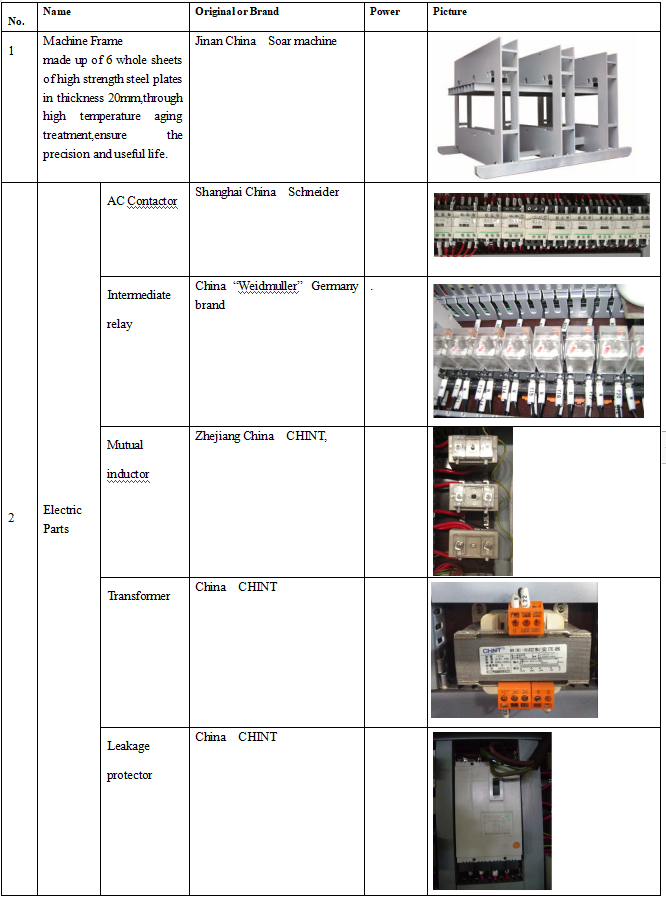

The main electrical equipments for control system adopt “Schneider” , “Weidmuller”, Taiwanese ”Delta”, Chinese ”CHINT”.

Number display current, voltage display, are easy to see. The micro computer temperature control equipment is adopted to control the temperature exactly.

The machine rack is made up of 6 whole steel plates excavated to avoid welding deformation.

The travel system for plate movement adopts our company’s patent, which matches the frequency governor, forming low speed to start, gradually speed up, high speed to move, low speed to stop. Ensure stable movement to avoiding translocation of the work piece.

ATM-3000II main specialties

1. Alarm designs for malfunction in PLC program are more comprehensive. The malfunctions are clear and easy to solve.

2. Installing German various pressure sensors,they accurately control the exact pressure digital.

3. Machine has 4 models(matt PVC,high gloss,veneer,silicon pre-press), we can choose correct model according to the different workmanship

4. Setup mandatory maintenance program in PLC.

Technical Specifications:

Exterior size: 13030mm×2230 mm×2150mm

Working plate size:3000mm×1320mm(inner size)

The maximum size of the work piece:2800X1200mm

The width of PVC film at least 1400mm

Maximum height of the work piece: 50mm

Rating working pressure: Positive pressure≤0.6Mpa

Negative pressure≥-0.095Mpa

Total Power: 56kw

(Upper heat transfer oil heating system:45kw,vacuum pump:2.2kw,hydraulic pressure system:5.5kw,circulating heat conduction oil pump:0.5kw,travel motor:1.1kwX2(two tables)=2.2kw)

Actual power consumption: About 13-15kw(electric and oil mixed heating with high energy storage,when the heat reached set temperature ,which can keep the temperature for long time,subsequent supplementary and keep heat just need nearly 1/3 of total power,the vacuum pump and hydraulic pressure system don’t start until needing)

Weight: 16T

Machine price

ATM-3000II (3000x1320mm) USD FOB QINGDAO,CHINA

3 Phase 380V 50Hz

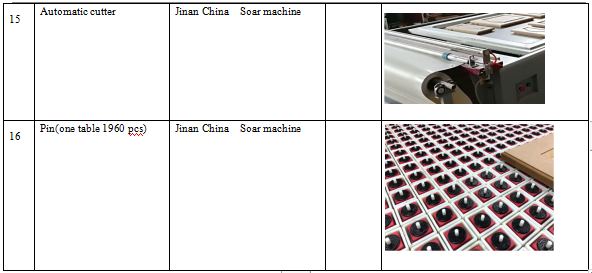

Automatic pull the PVC film and cut off the PVC film

Automatic unloading by overturning platform

Automatic rotating 12 rollers PVC support

Payment: 30% deposit, balance 70% before shipment

Delivery time: 50 working days after receiving deposit.

Packing material: EPE film+ preservative film

Maine machine

Accessories package

Working tables

ATM-3200II Main parts list

IV Free spare parts list

|

No. |

Name /type |

Unit |

Q'ty |

|

1 |

Schneider contractor /0910 |

Pc |

1 |

|

2 |

Schneider contractor / 2510 |

Pc |

2 |

|

3 |

Phase order protector |

Pc |

1 |

|

4 |

Power Swich |

Pc |

1 |

|

5 |

Mid-relay 2NJ,4NJ |

Pc |

2 |

|

6 |

Temperature controller |

Pc |

1 |

|

7 |

Thermocouple |

Piece |

1 |

|

8 |

DN40 valve cushion |

Pc |

1 |

|

9 |

Limit switch |

Pc |

4 |

|

10 |

hook knives |

Pc |

2 |

|

11 |

cutter |

Pc |

2 |

|

12 |

Vacuum oil |

L |

4 |

|

13 |

seal strip |

M |

8.8 |

|

14 |

seal strip |

M |

8.8 |

|

15 |

906 glue/906 |

Pc |

1 |

|

16 |

gas pipe joint |

Pc |

10 |

|

17 |

Positve and negative gauge |

Pc |

1 |

|

18 |

Negative gauge |

Pc |

1 |

|

19 |

Current gauge |

Pc |

1 |

|

20 |

Huydraulin rising relief valve |

Pc |

1 |

|

21 |

Huydraulin rising relief valve |

Pc |

1 |

|

22 |

Huydraulin gasket ring |

Set |

1 |

|

23 |

Oil cylinder seal ring |

Set |

1 |