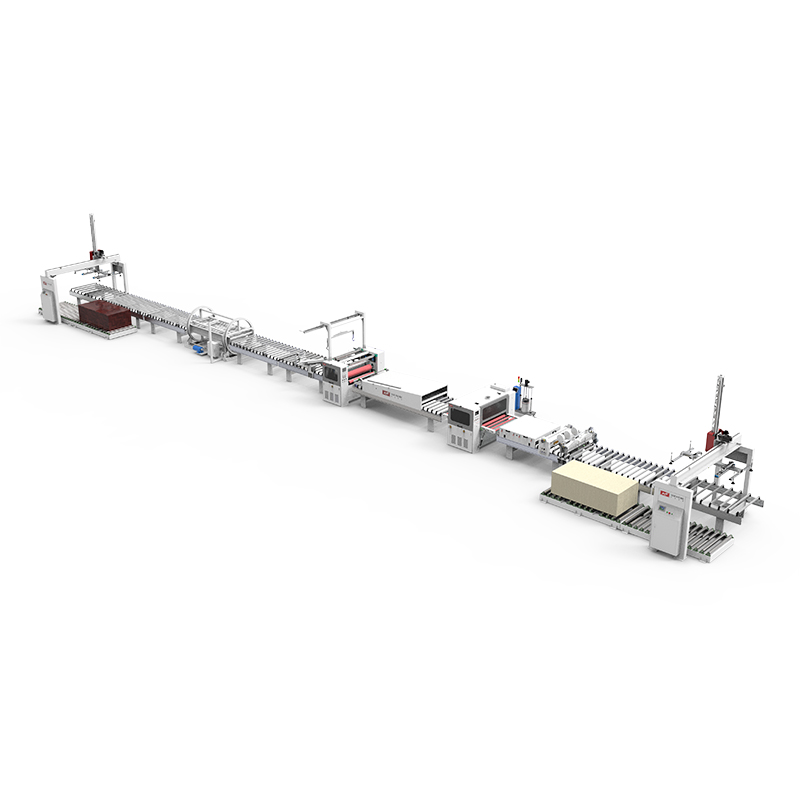

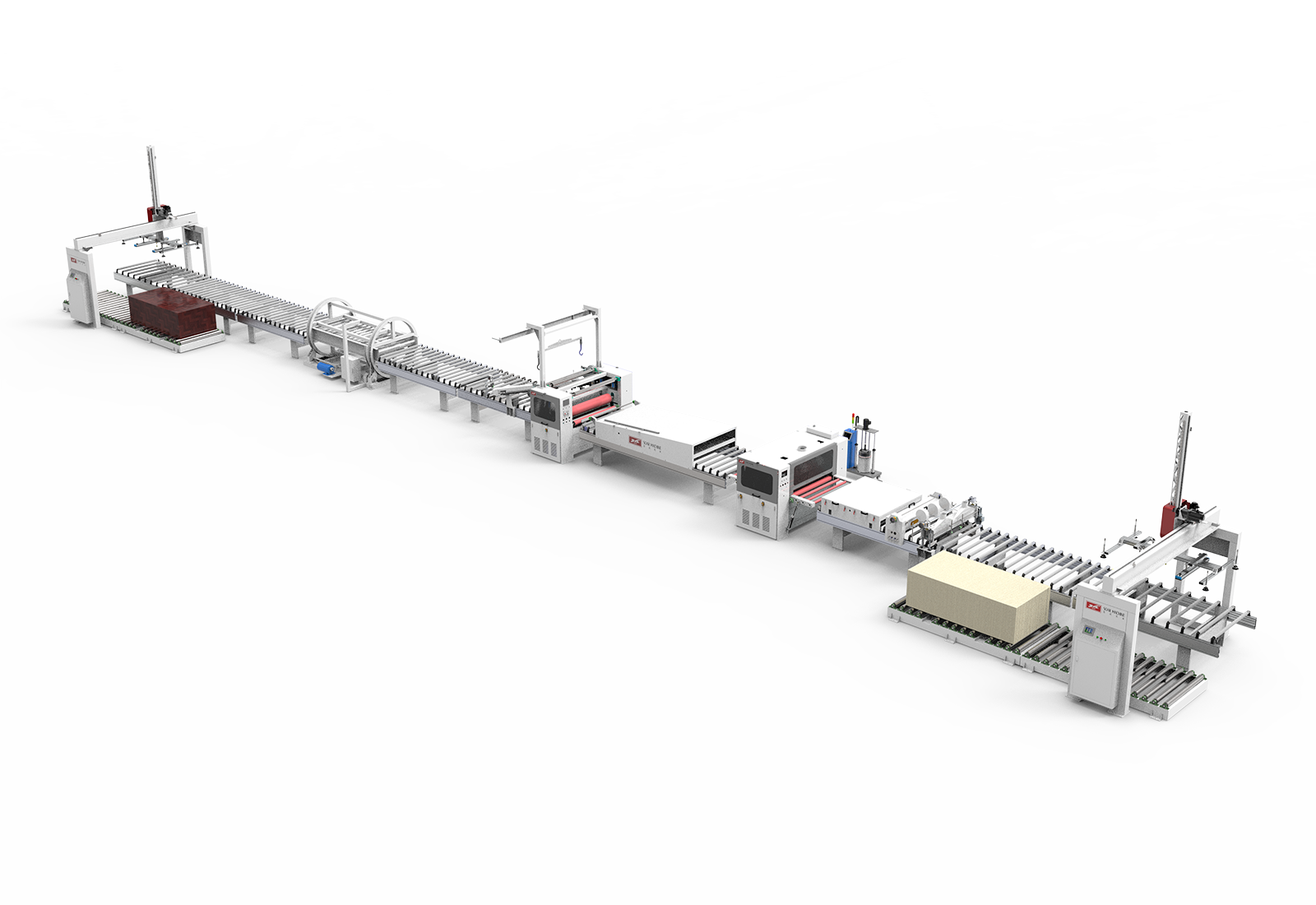

PT-1300PUR laminating machine

General Introduction

This production line is designed for high-level laminating, suitable with PUR adhesive for high-glossy PVC PET, acrylic panel, melamine,honeycomb plate,sandwich door panel,etc.

Equips list

| No. | process | Name | Model | Note |

| 1 | Auto loader | Gantry loader | AKT-SL-00 | With steel trans roll |

| 2 | transport | conveyor | AKT-SS1-00 | |

| 3 | Heat and dust remove | Remover and heater | AKT-JR-00 | With silicone roll |

| 4 | Glue apply | PUR coater | AKT-TJ-00 | With PUR melter |

| 5 | Heat and single manual | Composite heater | AKT-BW-00 | With silicone roll |

| 6 | lamination | Laminator | AKT-TH-00 | With crane |

| 7 | Edge cut | Horizontal cuter | AKT-XB-00 | |

| 8 | Following cut | Following cutter | AKT-GZQD-00 | With silicone roll |

| 9 | transport | Silicone conveyor | AKT-SS2-00 | |

| 10 | turnover | Turnover machine | AKT-FB-00 | |

| 11 | transport | Silicone conveyor | AKT-SS3-00 | |

| 12 | Auto unloader | Gantry unloader | AKT-XL-00 | With steel trans roll |

| 13 | Glue coat | PUR coater | AKT-AD-200 |

Equips parameter

01 gantry loader

Model :AKT-SL-00

This machine drive by servo motor, loading fast and accurately, save man staff.

parameters

| size | L3700×W3500×H4000mm |

| Work length | 2000-2500 mm |

| Work width | 800-1300 mm |

| Work weight | 50KG max |

| Loading speed | 4-8/min |

| Pallet height | 1200mm max |

| horizontal servo power | 1.8kw |

| Vertical servo power | 1.3kw |

| Capacity power | 3.1kw |

| voltage | 380V |

instruction

sucker vehicle drive and lift by servo motor, work flexibly and located accurately.

sucker vehicle move on accurate line rail, fast and quiet.

move by strong steel toothed belt, no need lubrication, and quiet.

take high flexibility cable and cycle ring, promise work stable in long time

Conveyor

model: AKT-SS1-00

this machine take Taiwan frequency governor, can work independently, also cooperate with whole production line

parameter

| size | L3000×W15500×H900mm |

| max work width | 1300 mm |

| transporter length | 3000 mm |

| transport height | 900-920mm |

| roll length | 1200mm |

| Roll gap | 220mm |

| transport power | 0.75kw |

| voltage | 380V |

remover and heater

Model: AKT-JR-00

this machine take Taiwan frequency governor, can work independently, also cooperate with whole production line

parameter

| Machine size | L2560×W2000×H1400mm |

| Max work width | 1300mm |

| Work height | 900-920mm |

| transport speed | 6-30m/min |

| Roll length | 1200mm |

| Roll gap | 220mm |

| Transport power | 0.75kw |

| Capacity power | 19.5kw |

| voltage | 380V |

Clean parameters

| Work height | 3-50mm |

| Brush size | Φ180×1350, length 52.5mm,Φ0.15, |

| Brush power | 0.75kw |

| voltage | 380V |

| Diameter of dust collector | Φ125×1 |

Clean instruction

this machine clean dust from sanding, to improve bonding quality

Preheat parameters

| infrared heating | 1.5kw×12pcs 380v |

| Capacity power | 18kw |

| voltage | 380V |

Preheat instruction

heating van takes infrared heating lights, and heat when sensor panels by photoelectric probe, stop heating when no sensor, so save energy max. panel preheating can enhance bonding adhesive on panels.

PUR coater

Model: AKT-TJ-00

This machine designed for coating PUR adhesive on top surface of panels.

equipped a set of coating device,which got a silicone wheel in diameter of 240mm with 8kw heating.

also a counting wheel in diameter 240mm with 8kw heating.

equipped a set of adhesive sharing device, which got a sharing wheels in diameter 240mm with 8kw heating.

Equipped a set of transport wheels, include 2 diameter 240mm silicone wheels.

parameter

| max transport width | 1400 mm |

| Work height | 900-920 mm |

| machine length | 1150 mm |

| Coating wheel diameter | 240 mm |

| Counting wheel diameter | 240 mm |

| Sharing wheel diameter | 240 mm |

| Transport wheel diameter | 2pcs×180 mm |

| Heating power | 3 x 8.0 KW |

| Max tem heating wheel | 200 ℃ |

| Max work width | 1250 mm |

| Work thickness | 3-100 mm |

| Coating wheel power | 1.5 KW |

| counting wheel power | 0.37 KW |

| Sharing wheel power | 0.37 KW |

| Transport wheel power | 1.5 KW |

| Coating lifter power | 0.37 KW |

| Sharing lifter power | 0.37 KW |

| Total power | about 30 KW |

| voltage | 380V 3P 4L |

| Feed speed | 5-25 m/min |

| Counting wheel speed | 1-6 m/min |

instruction

feed wheel controlled by frequency governor, coating wheel power 1.5kw.

0.37KW,counting wheel power 0.37kw.

Sharing wheel power 1.5kw, transport wheel 1.5kw

coating device and sharing device are independently four-poster support structure, and equipped automatic lift device, which can lift separately or together.

manually operate counting wheel,and showed in numbers.

Coating device takes a inverted station for cleaning adhesive easily; and observation window before and after coating.

Touching screen and emergency stop

Composite heater

Model: AKT-BW-00

parameters

| Machine size | L3600×W1600×H1200mm |

| Work height | 880-920mm |

| Max work width | 1300mm |

| Transport speed | 5-30m/min |

| Roll length | 1200mm |

| Rolls gap | 220mm |

| Transport power | 0.75kw |

| voltage | 380V |

Instruction

transported by rolls and got panel location device.

photoelectric switch sensor panel, and stop automatically.

manually start transport device.

Equipped location device on lifters.

Laminator

Model: AKT-TH-00

This machine is designed for coating adhesive and laminating fiberboard,honeycomb papers,particleboard.

Equipped four rolls presser which two press rolls and two reverse support rolls.

Top two press rolls can be adjusted by motor with button.

Bottom reverse support rolls are fixed on support shelf.

parameters

| Machine size | L2500×W1000×H1650mm |

| Max work width | 1300mm |

| Work thickness | 3-100mm |

| Work height | 880-920mm |

| Diameter of rolls | 4×φ240mm |

| Feed speed | 5-25m/min |

| Transport power | 3×1.5 kw |

| Lifter power | 0.37kw |

| voltage | 380V |

| Capacity power | 5kw |

Instruction

top press rolls adjusted by air pressure, which easy to open.

equipped automatic lift device for top press rolls.

This device is designed for pressing bonding panels, equipped two material roll system, which tightness can be adjusted

Touching screen and emergency button on control board.

Crane :JMDZ-600

This device is for lifting roll material to work position, fast and safe, save labor.

parameters

| Capacity load | 600kg |

| Capacity power | 2kw |

| voltage | 220V |

Horizontal cutter

Model: AKT-XB-00

This device is for cut redundant material after lamination, cut by cycle-cutter, and moved by high frequency motor

parameters

| Machine size | L2000×W1600×H920mm |

| Max work width | 1250 mm |

| Max transport length | 2000 mm |

| Transport height | 900-920mm |

| roll length | 1200mm |

| Rolls gap | 220mm |

| Transport power | 0.75kw |

| High frequency motor | 120W |

| Capacity power | 0.87kw |

| voltage | 380V |

this device takes Taiwan frequency governor, can work independently or cooperate with production line.

Following cutter

Model: AKT-GZQG-00

this device is for cutting roll material between panels after lamination.

Cut material synchronous automatically, would not damage lamination effect.

parameters

| Machine size | L3500×W1700×H1700mm |

| Max work width | 1250mm |

| Work height | 900-920mm |

| Transport speed | 6-20m/min |

| Transport power | 0.75kw |

| cut motor | 6N.M |

| Move motor | 6N.M |

| Synchronous power | 0.75kw;3000r/min |

| Capacity power | 5kw |

| voltage | 380V |

silicone conveyor

Model: AKT-SS2-00

parameters

| Machine size | L3000×W1600×H900mm |

| Max work width | 1300 mm |

| Transport length | 3000 mm |

| transport height | 880-920mm |

| Roll length | 1200mm |

| Rolls gap | 220mm |

| Transport power | 0.75kw |

| voltage | 380V |

this machine takes Taiwan frequency governor, can work independently or cooperate whole production line.

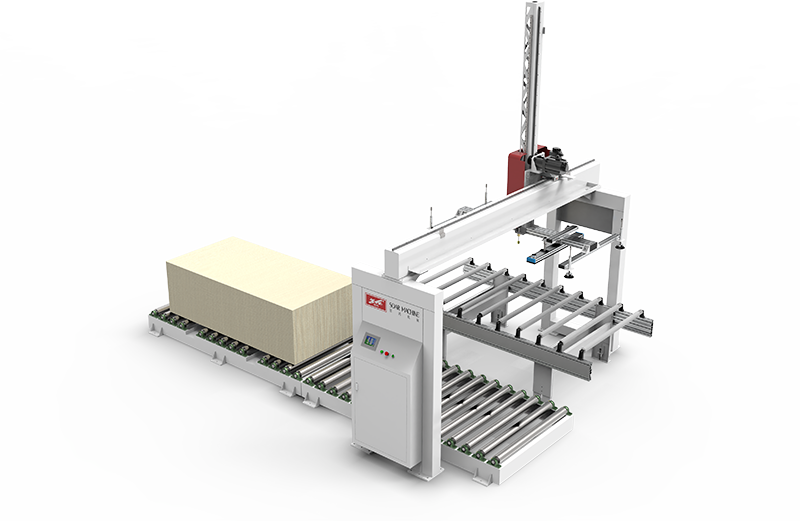

Gantry unloader

Model: AKT-XL-00

This device is drive by servo motor, loading fast and accurately, save labor.

parameters

| Machine size | L4600×W1300×H4000mm |

| Work length | 2000-2500 mm |

| Work width | 800-1300 mm |

| Work load | 50KG max |

| Unloading speed | 4-8 Times/min |

| Stacking height | 1200mm max |

| Vertical servo motor | 1.8kw |

| Horizontal servo motor | 1.3kw |

| Capacity power | 3.1kw |

| Voltage | 380V |

instruction

sucker vehicle drive and lift by servo motor, work flexibly and located accurately.

sucker vehicle move on accurate line rail, fast and quiet.

move by strong steel toothed belt, no need lubrication, and quiet.

take high flexibility cable and cycle ring, promise work stable in long time

touching screen show stacking machine work state and adjust parameters, convenient and flexible.

connected with main control system, operate easily.

PUR coater

Model: AD-200

Equipped for PUR wrapping, suitable for international 55 gallon bucket. This device connected by communication port with wrapping machine, provide melted PUR adhesive for profile wrapping stably.

This device take German LENZE frequency governor, best motor, and SCHNEIDER electrics.take touched mankind screen and PLC control.

parameters

| Bucket size | 200kg(55galon) |

| Inside diameter | φ571mm |

| voltage | AC220V/50HZ |

| Heating power | 15KW |

| Temperature control | 0--180℃ |

| Work pressure | 0.4~0.8MPa |

| Disc | Max:1100mm |

| Max motor speed | 60rpm |

| Max output pressure | 50kg/cm2 |

| Melt capacity | 1-120kg/h |

| Control system | PLC+touch screen |

| Insulation | yes |

| Temperature warning | yes |

| Adhesive burnout warning | yes |

| Pack size | 1600x1000x1850mm |

main technical charters

1. disc type adhesive machine made by 3 parts:

Main machine, pipes, manual/automatic scraper. And with function of upper and lower limit warning,adhesive allowance check, and frequency unfunction warning.

2. Progressive type melting: heating disc is above adhesive, only top part connected with heating disc and melted, then left part wont heated, so avoid adhesive aging because of long time heating

3. Adhesive separated from air when heat melting. There is O type sealing between disc and bucket,promise no connection with water in air, so satisfied PUR condition.

4. Disc made of aluminum alloy, and machined by CNC carefully, and sintered in deep penetration. It is bonding-prof,melted adhesive cleaned easily, so avoid adhesive carbonation, keep best state of adhesive bonding, and reduce jam.

5. Adhesive output adjusted by infinity variable speed,run by accurate gear pump, motor adjusted by infinity frequency, control output accurately.

6. Intelligent protection for main motor: main motor cannot start before heating disc arrived lower limit temperature, enhance protection to equipment.

7. adhesive bucket empty warning:

Quipped sensor behind main air cylinder, there is warning when adhesive run out.