TM2580C Multi-function membrane press machine

Function

It is used to work on various high-profile PVC, hot transfer and single veneer.

Features

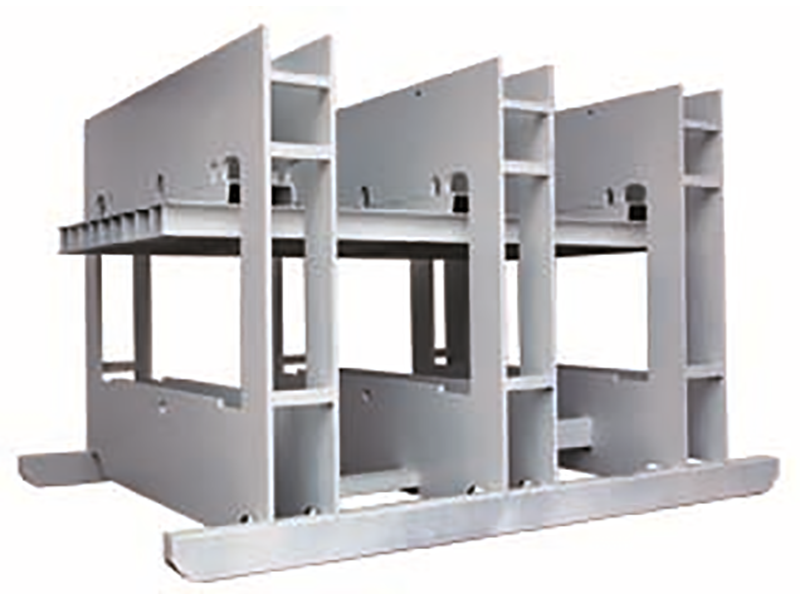

1. 6 pcs of steel plates in 25mm machined down without deformation. And installed in power point. Provide strong structure.

2. working table running controlled by DELTA frequency transformer; starting in low speed, running fast and end in low, which

3.DELTA PLC controller used for operation system, and touch-screen automatically convenient to control.

4. Vacuum pump Made in China with Germany technology straight-through theory, good working, and easy maintenance. Also can choose German BECKER original pump

5.Take SCHNEIDER 0910、2510 contactor, Weidder miller intermediate relay , and DELTA DVP-32ESO.

6. With theory of plug-in mounting, Taiwan COMPASS hydraulic system run promptly with large capacity, and seldom break down, use 5s to load hydraulic pressure which improve working efficiency.

Technical Specifications

Exterior size: 10030mm×2230 mm×2150mm

Working plate size: 2580mm×1270mm(inner size)

Maximum height of the work piece : 50mm (including back board)

Rating working pressure: positive pressure≤0.6Mpa negative pressure≥-0.095Mpa second loading pressure: 0.4Mpa.

General Power: 55kw

Actual power consumption: about11kW

Weight: 12.7T

Key to make high-glass PVC product (if can make high-glass, it is easy to make matt normal PVC):

TM2580H Membrane press machine can make perfect high-gloss pvc board. If want to keep high-glass PVC shining, without loss of gloss, have to finish pressing within 91℃, once exceeded, high-gloss will lose. But in this degree, PVC hasn’t soften enough to finish sticking, so need load a big pressure to shape the half-soft PVC. Also heat is from up board, temperature of the work piece edge is low, so by “lower heating” to rise the temperature of edge, then improve PVC softened to finish perfect shaping. Meanwhile, vacuum shaping glue needs heat to activate for bonding, there are 2 kinds: single component (60 degree) and double components (80 degree).for promising quality, suggest to take double components glue, so the temperature of working piece edge cant be too low, which should be the range 80-91℃, “lower heating” can assist finishing.(Due to those above, suggest make high-glass by plate or simple design)

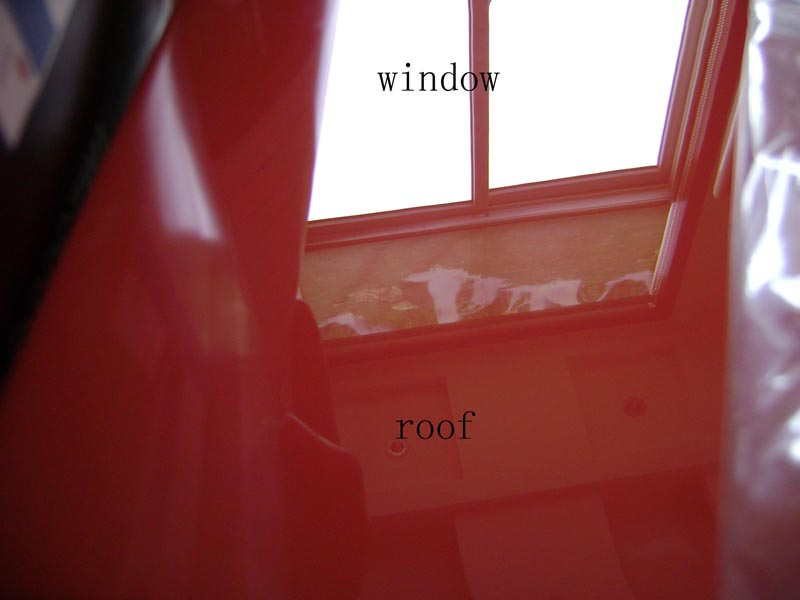

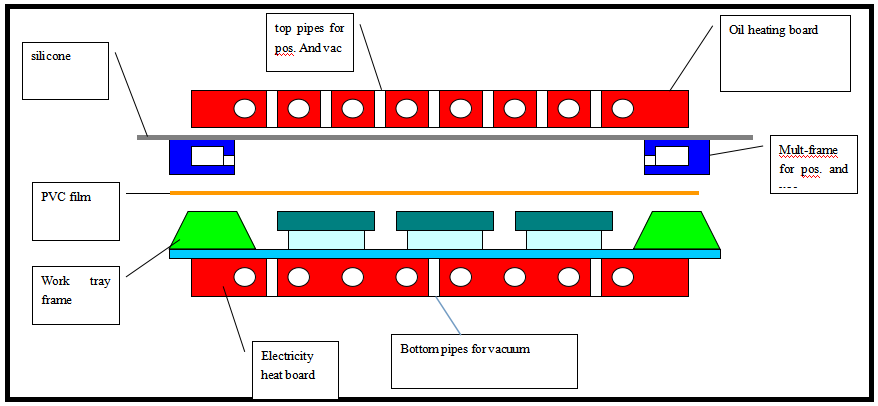

Work theory of pressure work twice (draw followed)

In most cases, machine works in mode of pressure once, no matter high-gloss or matt pvc.

1.When standby, silicone adsorbed to ‘oil heating board’ to be heated,

2.then ‘work tray’ move in and rise up,

3.now ‘silicone’ release down to be a circle (how much the circle can be controlled).

4.Then ‘mult-frame’ start to vacuum, adsorb ‘pvc’ and ‘silicone’ to be together for heating.

5.Heating timer finished, Vacuum work form ‘bottom pipes’,

6.then positive pressure loaded from mult-frame. Press pvc spliced on product.

If pvc break in this case, sensors will monitor that, and PLC automatically load positive pressure from top pipes, work on silicone. So work twice is a process that makeup in case of accident damage.

And based on this, more functions extended, you can work silicone only, or silicone first, then positive again. All modes set in PLC. It promise quality and save silicone from often use. Also fit many technologies, provide choices for different works.

Advantage of TM2580H: consider human design

1.warn suggestion set in PLC control, make fault clear before you, easy to check and fix

2.sensors placed in whole machine, monitor the whole working process.

If find abnormal, could deal by mode in PLC control which can promise the quality of working.

3.Reduce the professional requirement for operator, if they don’t know PVC and parameter setting well, also can finish the working well.

4.If PVC broken inside machine, it will be detected by sensors and start the remedy program (working twice) which promise the processing finished successfully.

Optional device for TM2580 Series machines: (need purchase separately)

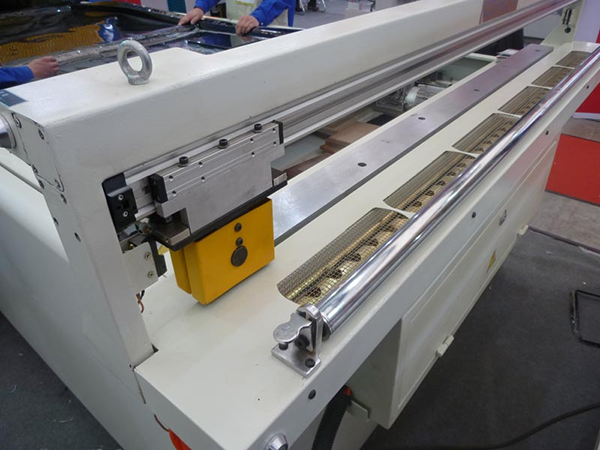

1. PVC Automatic cutting device , generally PVC in roll of 150-300m, need cut to different length when working. this device can raise working efficiency, reduce waste by wrong operation and lower labor intensity.

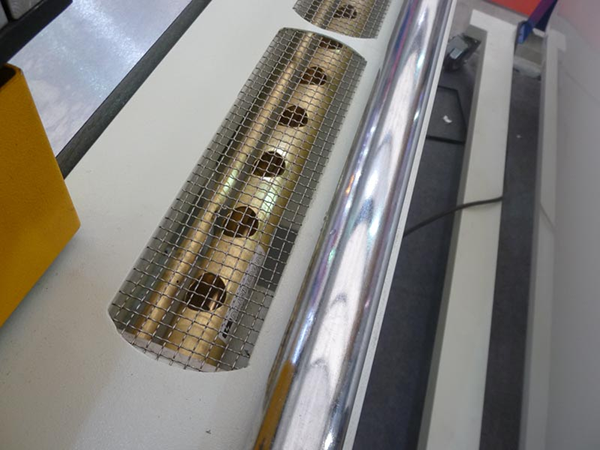

2. static electricity disposing device. PVC film get much static electricity, so dust in air and working table will adsorbed to reverse side of pvc, which will destroy the perfect of brightness. Disposing static device takes high voltage ion blow-out by compressed air to remove static (picture as above).

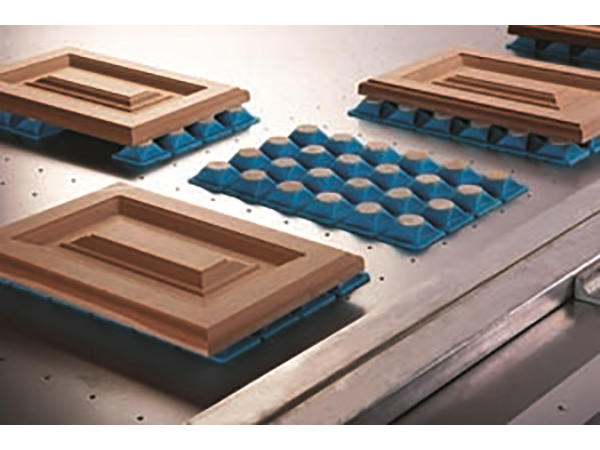

3. Magnetic block. Generally backing boards confuse most customers; magnetic blocks can reduce using wood or MDF for backing. Picture followed (But it is not obvious if many specifications for work piece, and not suitable for bad quality PVC)

4. Multi Volumes of PVC shelf: For now we are making third generation, divided to 6 and 12 reels. Picture followed is second generation.